Cryogenic Nozzle Check Valves

-

PRODUCT MODEL

- DKV-NCK Nozzle check valve

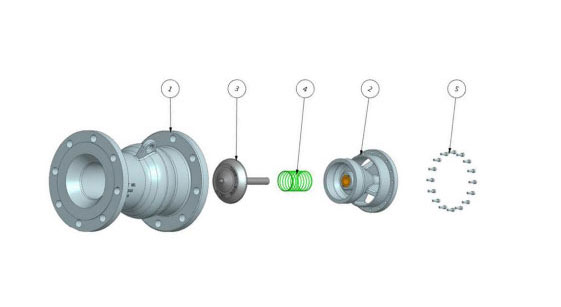

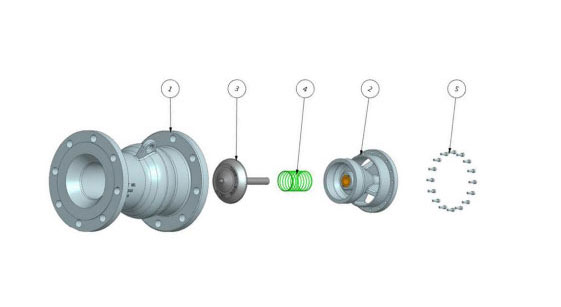

Drawing And Part List Of Nozzle Check Valves

-

DKC

| No. |

Part |

| 1 |

BODY |

| 2 |

DIFFUSER |

| 3 |

DISC |

| 4 |

COIL SPRING |

| 5 |

DIFFUSER BOLT |

VALVE FEATURES

- Designed by Computational Fluid Dynamics (CFD)

- Metal to Metal Seated design.

- Tight shut-off is obtained by means of a metal-to-metal sealing

- Spring loaded disc design allows mounting in any orientation

- Short stroke length reduces closure time and minimizes water hammer

- Low Pressure drop to avoid Cavitation and turbulence

- Short light weight Disc & Fast closing Spring design protects the piping against sudden Surge

STANDARD COMPLIANCE

- The face to face dimension shall be in accordance with API 6D, ASME B16.10

PRODUCTION RANGE

- Valve Size : 50mm (2in) ~ 1,500mm (60in)

- Working Temperature : -196℃ ~ +650℃

- Working Pressure : up to 425 bar

PPLICABLE FLANGE

- KS / JIS 5K / 10K / 16K / 20K / 30K / 40K / 63K

- BS EN1092-1 PN6 / PN10 / PN16 / PN25 / PN40 / PN63 / PN100

- ASME B16.5, B16.47 SR.A / B CLASS150 / 300 / 600 / 900 / 1500 / 2500

- AWWA C207 CLASS B / D / E

DKC

| Size |

150A (6”) ~ 700A (28”) |

| APPLICABLE FLANGE STD. |

ASME B16.5 Class 150 ~ Class 1500

JIS B 2220 10K ~ 64K |

| TEMPERATURE RANGE |

Low Temperature Carbon Steel |

- 45°C to 300°C (-50°F to 572°F ) |

| Stainless Steel |

- 196°C to 300°C (-320°F to 572°F) |

| Duplex |

- 196°C to 300°C (-320°F to 572°F) |

| APPLICATION |

Chemical, Oil & Gas Industries |

Steam Injection System |

| Residual Heat Removal System |

Power Station, Water Pumping Stations |

| Nuclear Power Plants |

Natural Gas, Refineries |

| Cracker Plant |

Critical Equipment Discharge |

| Containment Isolation |

Gas Compressor Unit |

| Water, Steam, Gas, Vacuum |

Offshore & Onshore Production Platform, FPSO |