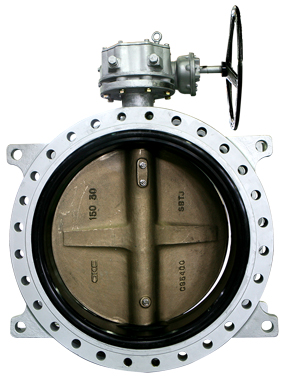

Concentric Rubber Seated Butterfly Valves

-

PRODUCT MODEL

- DKV-CRW Concentric rubber seated

wafer type butterfly valve

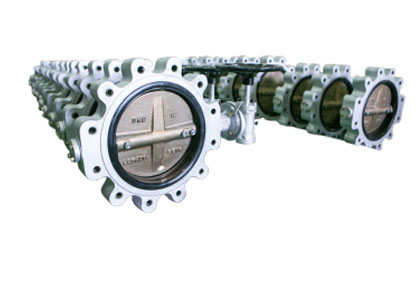

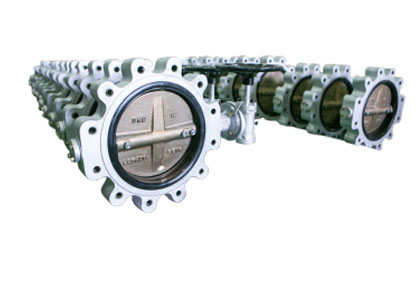

- DKV-CRL Concentric rubber seated

lug type butterfly valve

- DKV-CRF Concentric rubber seated

flange type butterfly valve

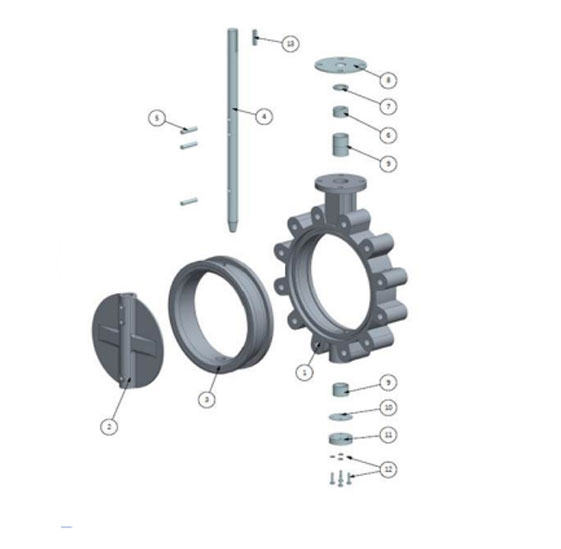

DRAWING AND PART LIST OF CONCENTRIC BUTTERFLY VALVES

-

DKC

| No. |

Part Name |

| 1 |

BODY |

| 2 |

DISC |

| 3 |

SEAT |

| 4 |

STEM |

| 5 |

DISC PIN |

| 6 |

PACKING |

| 7 |

PACKING GLAND |

| 8 |

GLAND FLANGE |

| 9 |

BEARING |

| 10 |

BOTTM GASKET |

| 11 |

BOTTOM COVER |

| 12 |

BOLT & WASHER |

| 13 |

KEY or SQUARE |

STANDARD COMPLIANCE

- Concentric butterfly valves conform to ISO 5752, KSV 7490, JIS F 7480, JIS B 2032, JIS B 2064, API609,BS5155, DIN2501

PRODUCTION RANGE

- Valve Size : 40mm (1-1 / 2 in) ~ 1,800mm (72 in)

- Rating Temperature : -20℃ ~ +80℃

- Working Pressure : up to 16 bar

APPLICABLE FLANGE

- KS / JIS 5K / 10K / 16K

- ASME B16.1 CLASS125, ASME B16.5 CLASS150

- ASME B16.47 SR.A / B CLASS150

- BS EN1092-1 PN6 / PN10 / PN16

- AWWA C207 CLASS B / D / E

SCHEMA OF CONCENTRIC TYPE

The valves shall be a 90° turn clockwise to close, no-jamming, and resilient seated valve for zero leakage service.

The valves shall be torque seated and designed in such a manner that the disc can not be rotated the seat without

the actuator. Also theses valves enable the fluid perfect shut-off regardless of the flow direction.

- Symmetric disc design ensures favourable flow characteristics and low pressure drop

- Concentric shaft ensures low operating torque

- Lining gives a good protection to valve body and acts as flange gasket

- - Shaft penetrates the valve seat

- - Limited choice of seating materials(Elastomer only)

OPERATIONS

The following operation of the valve is possible depending on the valve location,

the type of work and service of the valve to be provided

- Manual lever operation

- Manual worm gear operation

- Hydraulic actuator operation

- Electric motor actuator operation

- Single or double acting pneumatic actuator operation

DKC

| Range |

Application |

| Size |

1-1/2"(40A) ~ 72"(1800A) |

| Fluid |

Water |

| Rating |

JIS 10K, ANSI 150#, PN10 |

| End Connection |

Wafer, Lugged, Flanged |

| Temp. Range |

NBR -20 ~ 80°C

EPDM -20 ~ 120°C

VITON -20 ~ 165°C |

| Materials |

Body |

Cast Iron, Ductile Iron, Cast Steel, Stainless Steel,

(Ni) Al Bronze, (Super) Duplex S.S etc. |

| Disc |

Stainless Steel, (Ni) Al Bronze, (Super) Duplex S.S etc. |

| Seat |

Rubber (EPDM, NBR, VITON etc.) |